AHH 02 Drainage And Seepage Tank

DESCRIPTION

The bed of the tank is made from painted mild steel. The sides of the tank are supported and sealed by a well proven method which allows free access to the interior and results in minimum sight obstruction. One side is of toughened glass to give good scratch free visibility over a long period of use while the other is made of aluminium which permits the insertion of pressure tapping points as required. The ends of the tank are made of steel plate.

Adjustable overflows are provided close to each end of the tank so that constant water levels may be maintained in each half of the tank. These may be lowered to a position close to the bed of the tank for some experiments to provide subsoil drainage. The equipment is self-contained, requiring only an initial fill with cold water and connection to the electricity supply. The sump tank can be emptied to a laboratory drain.

TYPICAL STUDENT EXPERIMENTS INCLUDE

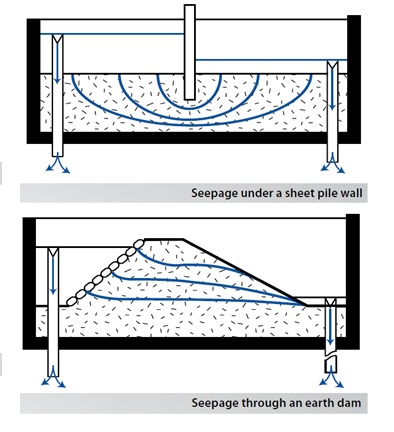

- Seepage underneath a sheet pile wall

- Seepage through an earth dam

- Control of seepage through permeable soils by sub-soil drainage

- Distribution of uplift pressure on hydraulic structures

- Reducing uplift pressure and lateral thrust by drainage

- Formation and behaviour of ‘Quicksand’

- Stability of an earth dam

- Draining an excavation site using wells

EXPERIMENTAL CAPABILITIES

- Flow line visualization

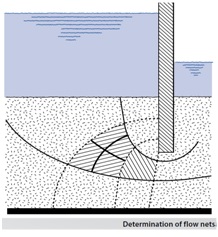

- Flow net construction

- Determining Seepage rates

- Verification of Darcy’s law

- Comparison of experimental results with analytical solutions

- determining flow nets in permeable media graphically

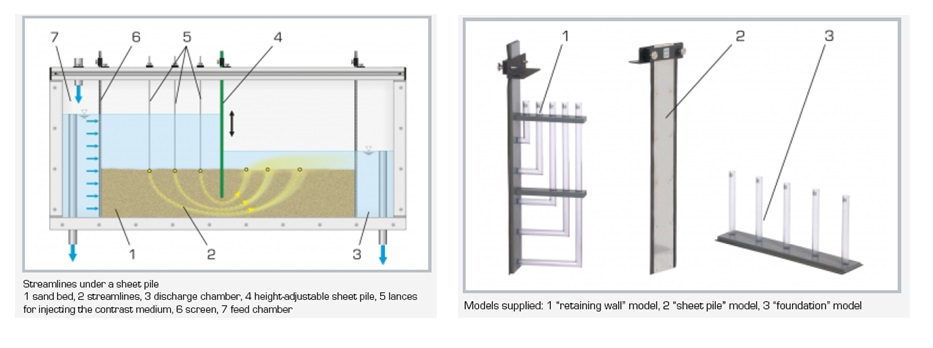

- streamlines under a sheet pile

- streamlines through an earth dam

- drainage at an open ditch

- determining the pressure curve at a foundation

- determining the pressure curve at a retaining wall

- groundwater levels over time in various Models

SPECIFICATIONS

- A self-contained facility for study of flow through permeable media

- The tank has a toughened glass front and aluminium back to permit the insertion of pressure tappings as required.

Six tapping points are provided

- The design of the side supports allows free access to the interior with minimum sight obstruction

- Supply includes sump tank, pump, starter and control valve. Also a dye injection system and a selection of models

- Comprehensive instruction manual with data sheets and student experiments

- Working section 1500mm x 100mm x 600mm

BASIC ACCESSORIES

- Foundation pressure plate

- Straight permeable membrane

- Curved permeable membrane

- Lateral pressure plate

- Tile drain

UTILITIES REQUIRED

Electricity supply: 220-240V/1ph/50Hz, 1A

Sand (1…2mm grain size)

TECHNICAL DETAILS

| Product & code | Drainage and seepage tank & Ahh – 02 |

| Experimental section | Tank made up of SS304 with one side toughened glass of 6-8 mm thickness

Size: LxWxH: 1500 x 102 x 625mm |

| Inclination of base of the tank | The inclination of base of the tank with respect to ground surface adjustable up to angle range of 00 -150. |

| No of piezometers | 13 nos on bottom and 6 no.s on back with 650 mm water manometer |

| Dye Injection system | Dye Injection system with 0.5 ltr capacity & three probes. |

| Pump | Max. flow rate: 4m3/h and Max. head: 4m |

| Sump Tank | MOC SS 304, Capacity 100 ltrs |

| Adjustable Overflows | Adjustable overflows provided close to each end of the tank so that constant water levels may be maintained. |

| Well Outlet | 2-3 nos of well outlet provided at the base of the tank to represent leakage layer at the base. |

| Weight And Volume (Approx.)

|

Gross weight: 150kg

Volume: 2.4m3 |

ABOUT OUR COMPANY

WE MANUFACTURERS WIDE RANGE OF PRODUCTS LIKE HEAT TRANSFER LAB EQUIPMENT, HYDRAULIC BENCH, HYDRAULIC MACHINES LAB EQUIPMENT, ETC. WE MANUFACTURE THESE PRODUCTS AS PER THE LATEST MARKET TRENDS AND DELIVER THESE AT USERS’ PREMISES WITHIN THE SCHEDULED TIME FRAME.

Contact Us

Have questions, comments or just want to say hello:

- mass_international99@yahoo.co.in

- 92156-00789 , 9215900789, 9812225689, 9812200689

- Regd. Office Works:

Plot No. 459, Sector – 2, Phase – 1, Industrial Estate Growth Centre,HSIIDC, Saha – 133104

GSTIN. No. 06ADYPK5042P1ZS

Website Design By | Design: Fame Digital Worlds by Fame Digital Worlds