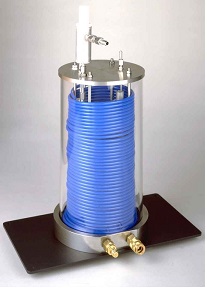

CRE 42 ISOTHERMAL PLUG FLOW TUBULAR REACTOR (Coiled Tube Type)

Description

Tubular reactors are continuously operated reactors. They enable economic production of large product quantities with a consistent quality. It is part of a device series that enables experiments with different reactor types. In conjunction with the supply unit, it is possible to examine the function and behaviour of a tubular reactor. The supply unit has a heating water circuit, all necessary connections, pumps, tanks for reactants and a product tank. It is mounted onto the supply unit with knurled bolts. The two pumps of the supply unit convey the reactants separately into the reactor. Two coiled tubes located in a water bath preheat the reactants. After preheating, each of the reactants flows through a nozzle. The nozzle outlets are located in a T-piece in such a way that the two reactants are mixed in the centre of the T-piece. The mixture enters into the helical tube in which the two reactants react. The mixture of product and unconverted reactants leaves the tube and is collected in a tank of the supply unit. The residence time of the reactants in the tubular reactor is adjusted via the speed of the pumps on the supply unit. The tube is also located in the water bath. The water bath is connected to the heating water circuit of the supply unit, which enables the user to examine the influence of the temperature on the reaction. An overflow ensures that the level of the water bath remains constant. The conversion in the tubular reactor is determined by measuring the conductivity. For this purpose, the reactor has an opening for a combined conductivity/temperature sensor. The sensor is included in the scope of delivery of the supply unit. Conductivity and temperature are digitally displayed on the switch cabinet of the supply unit. In addition, the measured values can be captured and processed with data acquisition software.

EXPERiMENTS

- Fundamentals of a Saponification reaction

- Conversion

- Depending on residence time

- Depending on the temperature

SPECIFICATION

- Tubular reactor for connection to supply unit

- Helical plastic tube as reactor

- 2 helical stainless steel tubes for preheating the reactants

- T-piece with 2 nozzles for mixing the preheated reactants

- Transparent PMMA tank as water bath for the reactor and for preheating for connection to the heating water circuit

- Sensor for measuring the conductivity and temperature

- Temperature control in the reactor

TECHNICAL DETAILS

| Product & Code | Isothermal Plug Flow Tubular Reactor (Coiled Tube Type) & CRE 42 |

| Reactor | – inside diameter: approx. 5,5mm

– reactor capacity: approx. 475mL – material: PA |

| Water Bath | – inside diameter: approx. 200mm

– capacity: approx. 1500mL – material: PMMA |

| Dimensions and Weight | LxWxH: 470x320x600mm

Weight: approx. 25kg |

| Required for Operation | Ethyl acetate, caustic soda (for Saponification reaction) |

| Scope of Delivery | 1 tubular reactor |

ABOUT OUR COMPANY

WE MANUFACTURERS WIDE RANGE OF PRODUCTS LIKE HEAT TRANSFER LAB EQUIPMENT, HYDRAULIC BENCH, HYDRAULIC MACHINES LAB EQUIPMENT, ETC. WE MANUFACTURE THESE PRODUCTS AS PER THE LATEST MARKET TRENDS AND DELIVER THESE AT USERS’ PREMISES WITHIN THE SCHEDULED TIME FRAME.

Contact Us

Have questions, comments or just want to say hello:

- mass_international99@yahoo.co.in

- 92156-00789 , 9215900789, 9812225689, 9812200689

- Regd. Office Works:

Plot No. 459, Sector – 2, Phase – 1, Industrial Estate Growth Centre,HSIIDC, Saha – 133104

GSTIN. No. 06ADYPK5042P1ZS

Website Design By | Design: Fame Digital Worlds by Fame Digital Worlds