EP 04 COMP ENGINE TEST SETUP THREE CYLINDER FOUR STROKE, PETROL

(COMPUTERIZED) DESCRIPTION

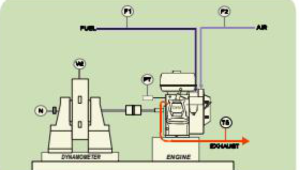

The setup consists of three cylinder, four stroke, Petrol (MPFI) engine connected to eddy current / Hydraulic type dynamometer for loading. It is provided with necessary instruments for combustion pressure and crank‐angle measurements. These signals are interfaced to computer through engine indicator for Pθ−PV diagrams.

Provision is also made for interfacing airflow, fuel flow, exhaust temperature and load measurement. The set up has stand‐alone panel box consisting of air box, fuel tank, manometer, fuel measuring unit, transmitters for air and fuel flow measurements, process indicator and engine indicator. Rotameters are provided for cooling water and calorimeter water flow measurement.

The setup enables study of engine performance for brake power, indicated power, frictional power, BMEP, IMEP, brake thermal efficiency, indicated thermal efficiency, Mechanical efficiency, volumetric efficiency, specific fuel consumption, A/F ratio and heat balance. Labview based Engine Performance Analysis software package “Vishleshan” is provided for on line performance evaluation.

FEATURES

- Morse test

- Online measurements and performance analysis

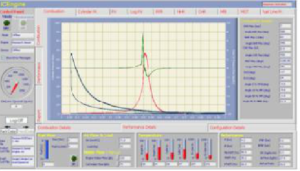

- PΘ‐PV plots, performance plots and tabulated results

- Data logging, editing, printing and export

- Configurable graphs

- IP, IMEP, FP indication

- Combustion analysis

EXPERIMENTS

- Study of engine performance (Manual mode)

- Study of engine performance (Computerised mode)

- Study of Morse test

UTILITIES REQUIRED

- Electric supply: Provide 230 +/- 10 VAC, 50 Hz, single phase

- Computer: With standard configuration

- Water supply: Continuous clean and soft water supply @5000

LPH, at minimum head of 10 m. Is needed. Provide tap with 1” BSP size connection.

SOFTWARE

“Vishleshan” is a Labview based powerful engine analysis software developed by Mass International for engine performance monitoring system. “Vishleshan” can fulfill most of the engine testing application needs including monitoring, reporting, data entry, data logging. The software evaluates power, efficiencies, fuel consumption and heat release. It is configurable as per engine set up. Various graphs are obtained at different operating condition. While on line testing of the engine in RUN mode Necessary signals are scanned, stored and presented in graph. Stored data file is accessed to view the data graphical and tabular formats. The results and graphs can be printed. The data in excel format can be used for further analysis.

TECHNICAL SPECIFICATIONS

| Product & Code | Engine test setup 3 cylinder, 4 stroke, MPFI, Petrol (Comp.) |

|---|---|

| Code Engine | Make Maruti, Type BS- IV, 3 Cylinder, 4 Stroke, Petrol (MPFI), water cooled, Power 27 KW at 5000 rpm, Torque 59 NM at 2500rpm,stroke 72 mm, bore 66.5mm, 796 cc, CR 9.2 |

| Dynamometer | Eddy current Type, water cooled |

| Propeller shaft | With universal joint |

| Air box | M S fabricated with orifice meter |

| Fuel Tank | Capacity 15 lit with glass fuel metering column |

| Calorimeter | Type Pipe in pipe |

| Piezo Sensor | Range 5000 PSI, with low noise cable |

| Crank Angle Sensor | Resolution 1 Deg, Speed 5500 RPM with TDC pulse. |

| Data acquisition device | Advantech/NI USB-6210, 16-bit, 250kS/s. |

| Piezo powering unit | Model AX 409 |

| Temperature Sensor | Type RTD, PT100 and Thermocouple, Type K |

| Temperature Transmitter | Type two wire, Input RTD PT100, Range 0–100 Deg C, O/P 4–20mA, Type 2wire, I/P TC, Range 0–1200 Deg C |

| Load indicator | Digital, Range 0 50 Kg, Supply 230VAC |

| Load sensor | Load cell, type strain gauge, range 0-50 kg |

| Fuel Flow Transmitter | DP transmitter, Range 0-500 mm WC |

| Air Flow transmitter | Pressure transmitter, Range (-) 250 mm WC |

| Software | “Vishleshan” Engine performance analysis software |

| Overall Dimensions | W 2000 x D 2500 x H 1500 mm |

The whole setup is well designed and arranged in a good quality painted structure.

ABOUT OUR COMPANY

WE MANUFACTURERS WIDE RANGE OF PRODUCTS LIKE HEAT TRANSFER LAB EQUIPMENT, HYDRAULIC BENCH, HYDRAULIC MACHINES LAB EQUIPMENT, ETC. WE MANUFACTURE THESE PRODUCTS AS PER THE LATEST MARKET TRENDS AND DELIVER THESE AT USERS’ PREMISES WITHIN THE SCHEDULED TIME FRAME.

Contact Us

Have questions, comments or just want to say hello:

- mass_international99@yahoo.co.in

- 92156-00789 , 9215900789, 9812225689, 9812200689

- Regd. Office Works:

Plot No. 459, Sector – 2, Phase – 1, Industrial Estate Growth Centre,HSIIDC, Saha – 133104

GSTIN. No. 06ADYPK5042P1ZS

Website Design By | Design: Fame Digital Worlds by Fame Digital Worlds