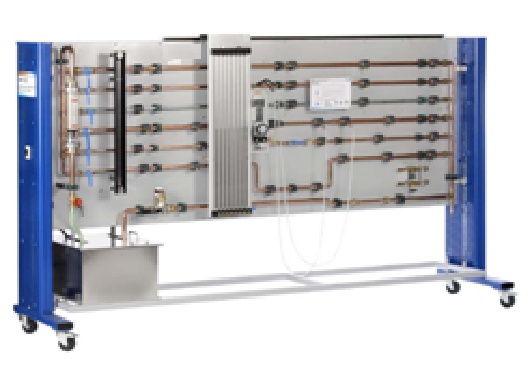

Knowledge of pressure losses in various pipe elements is a key factor in designing pipe systems. The trainer allows the determination by experiment of these important coefficients and the investigation of the pressure curve in typical pipe sections. The trainer comprises three straight pipe sections made of different materials and with different diameters. Also included are: a pipe section with pipe bends, a pipe section with contraction and enlargement and a pipe section with interchangeable valves and fittings. The large length of the pipe sections of 2,5m and the fact each section is fitted with at least five pressure measuring points means it is possible to obtain very accurate measurements and demonstrate the linear reduction in pressure in a pipe. A rotameter and a volumetric measuring tank are included for comparison measurements and calibrations. The volumetric measurement using a stopwatch gives highly accurate results even at low flow rates. Tube manometers, a Bourdon tube pressure gauge and a differential pressure sensor are provided for pressure and differential pressure measurements. The pressure measuring points are designed as annular chambers for accurate pressure measurement. A movable manometer panel saves space and allows for optimal accessibility. The trainer includes a closed water circuit with tank and submersible pump. This means the trainer can be used independent of the laboratory network. The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

The whole setup is well designed and arranged in a good quality painted structure.

WE MANUFACTURERS WIDE RANGE OF PRODUCTS LIKE HEAT TRANSFER LAB EQUIPMENT, HYDRAULIC BENCH, HYDRAULIC MACHINES LAB EQUIPMENT, ETC. WE MANUFACTURE THESE PRODUCTS AS PER THE LATEST MARKET TRENDS AND DELIVER THESE AT USERS’ PREMISES WITHIN THE SCHEDULED TIME FRAME.

Have questions, comments or just want to say hello:

GSTIN. No. 06ADYPK5042P1ZS

Website Design By | Design: Fame Digital Worlds by Fame Digital Worlds