IMI 107 MULTIPROCESS TRAINER

DESCRIPTION

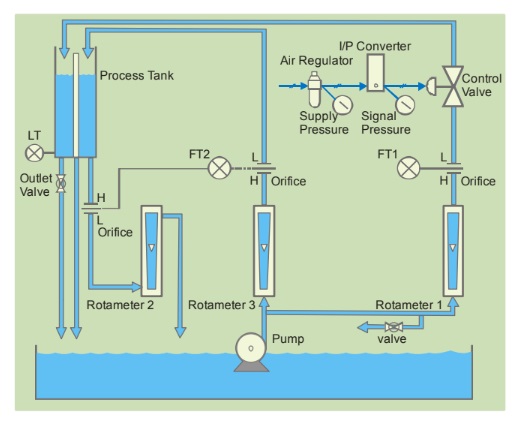

The setup is designed to understand the advanced control methods used for complex processes in the industries. Different experiments like Flow, level, cascade, feed forward and ratio control can be configured and studied with the setup. It consists of water supply tank, pumps, level transmitter, transparent level tank, and orifice meters with differential pressure transmitters, rotameters, pneumatic control valve, I/P converter and data acquisition device. These units along with necessary piping are mounted on stand-alone type structure. The process signals from level transmitter and flow transmitters are connected to Multifunction I/O & NI-DAQMX which is connected to computer through USB port communication.

FEATURES

- Flow, Level, Cascade, Feedforward &ratio control

- Closed loop water circulation

- ON-Off & PID operation

- Non-corrosive wetted parts

RANGE OF EXPERIMENTS

- Study of open loop response (Manual control)

- Study of on/off controller

- Study of proportional controller

- Study of proportional integral controller

- Study of proportional derivative controller

- Study of proportional integral derivative controller

- Tuning of controller (Open loop method)

- Tuning of controller (Closed loop method)

- To study stability of the system (Bode plot)

- To study cascade control system

- To study feed forward control system

- To study ratio control system

UTILITIES REQUIRED

- Electric supply: Provide 230 +/- 10 VAC, 50 Hz, single phase

- Water supply: Distilled water @20 liters.

- Air supply: Clean, oil and moisture free air, pressure 2 Bar, consumption 50 LPH

- Computer:IBM compatible with standard configuration.

SOFTWARE

Specially developed Labview based software is provided which helps in learning the principles of control. Different experiments can easily be selected and studied. The software is easy to use, flexible & with features like Data access, trend plots, Data logging, Printing, Data export.

Specifications

| Product & code | Multiprocess trainer & IMI 107 |

| DAQ device | NI USB-6001, 14 bit, 20KS/S Multifunction I/O and NI-DAQMX, Analog input 4, Analog output 2 |

| Communication | USB port |

| Differential pressure transmitter | Type Capacitance, two wire, Range 0–200 mm, Output 4– 20 mA sq.root (2 Nos) |

| Level transmitter | Type Electronic, two wire, Range 0–250 mm, Output 4–20 mA |

| I/P converter | Input 4-20mA, Output 3-15 psig |

| Powersupply | Model S-15-24, Output 24 VDC, 0.7 A |

| Control valve | Type: Pneumatic; Size: 1/4″, Input: 3–15 psig, Air to close, Characteristics: linear |

| Rotameter | 10-100LPH (3 nos) |

| Pump | Fractional horse power, type submersible |

| Process tank | Transparent, Acrylic, with 0-100% graduated scale |

| Supply tank | SS304 |

| Flow measurement | Orifice meter (3 nos) |

| Air filter regulator | Range 0-2.5 kg/cm2 |

| Pressure gauge | Range 0-2.5 kg/cm2 (1 no), 0-7 kg/cm2(1 no) |

| Overall dimensions | 600Wx500Dx1600H mm |

ABOUT OUR COMPANY

WE MANUFACTURERS WIDE RANGE OF PRODUCTS LIKE HEAT TRANSFER LAB EQUIPMENT, HYDRAULIC BENCH, HYDRAULIC MACHINES LAB EQUIPMENT, ETC. WE MANUFACTURE THESE PRODUCTS AS PER THE LATEST MARKET TRENDS AND DELIVER THESE AT USERS’ PREMISES WITHIN THE SCHEDULED TIME FRAME.

Contact Us

Have questions, comments or just want to say hello:

- mass_international99@yahoo.co.in

- 92156-00789 , 9215900789, 9812225689, 9812200689

- Regd. Office Works:

Plot No. 459, Sector – 2, Phase – 1, Industrial Estate Growth Centre,HSIIDC, Saha – 133104

GSTIN. No. 06ADYPK5042P1ZS

Website Design By | Design: Fame Digital Worlds by Fame Digital Worlds