WT-15 ANAEROBIC DIGESTER

DESCRIPTION

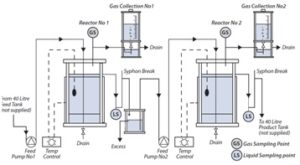

The anaerobic digester set up comprises of two 5 litre upward-flow packed bed reactors with feed rate and temperature control facilities. The reactors may be operated in series or parallel. A buffer vessel between the reactors permits discharge of excess flow from the first reactor when the second reactor is operated in series but at a lower flow rate. The flow rates to the vessels are set and controlled by calibrated peristaltic pumps. The temperature of each reactor is controlled by an electric heating mat wrapped around the external wall. Digital Temperature Controller is used to set reactor temperatures separately set at any desired value in the range ambient to 55◦C.

The gas from each reactor is taken to a volumetrically calibrated collector vessel operating by water displacement. A constant head, liquid seal device ensures that the gas pressure in the reactor is maintained at a constant value throughout the test run. The collected gas can be exhausted from the vessel and it can be re-filled with water during a run without breaking the liquid seal. Liquid and gas sampling points are located at all strategic points around the reactors. Non-return valves and liquid seal syphon breaks are included in the process pipework to ensure each reactor operates at a constant volume without the ingress of air or the danger of accidental syphonic action. The equipment is mounted on a base with an integral drain channel to cope with spillages and wash down.

EXPERIMENTS

- To study the characteristics of Anaerobic Digester.

- To determine the optimum operating temperatures, feed rates and ratios.

- To study the effect of pH and influent nutrient concentration.

Utilities REQUIRED

- Electrical supply: 220-240V/1ph/50Hz@5A

- Analytical equipment as exists in most water quality laboratories for measurement of pH, BOD, COD, alkalinity, total volatile acids and suspended solids

TECHNICAL SPECIFICATIONS

| Product & Code | Anaerobic Digestor & WT-15 |

| Reactors (2 No.) | Two, identical reactors: nominal capacity: 5 litres (approx.)

packed volume: 4 litres150mm dia x 250mm height |

| Reactor packing: | 25mm diameter Bio-balls |

| Feed pumps (2 No.) & Measurement | Peristaltic pumps |

| Gas collection vessels (2 No.) | linear scale, 0-5 litre capacity |

| Feed Tank | 30 ltr MOC PVC |

| Product Tank | 50 ltr MOC PVC |

| Reaction Heater (2 No.) | 200W each |

| Control panel | Digital Temp. Controller: 0- J.99.9°C (For Hot Water Bath), On/off switch, Mains Indicator etc.

Temperature Sensor: RTD PT-100 type |

| The setup is painted with good quality paints & mounted on a strong support. | |

ABOUT OUR COMPANY

WE MANUFACTURERS WIDE RANGE OF PRODUCTS LIKE HEAT TRANSFER LAB EQUIPMENT, HYDRAULIC BENCH, HYDRAULIC MACHINES LAB EQUIPMENT, ETC. WE MANUFACTURE THESE PRODUCTS AS PER THE LATEST MARKET TRENDS AND DELIVER THESE AT USERS’ PREMISES WITHIN THE SCHEDULED TIME FRAME.

Contact Us

Have questions, comments or just want to say hello:

- mass_international99@yahoo.co.in

- 92156-00789 , 9215900789, 9812225689, 9812200689

- Regd. Office Works:

Plot No. 459, Sector – 2, Phase – 1, Industrial Estate Growth Centre,HSIIDC, Saha – 133104

GSTIN. No. 06ADYPK5042P1ZS

Website Design By | Design: Fame Digital Worlds by Fame Digital Worlds